Energy-from-Waste

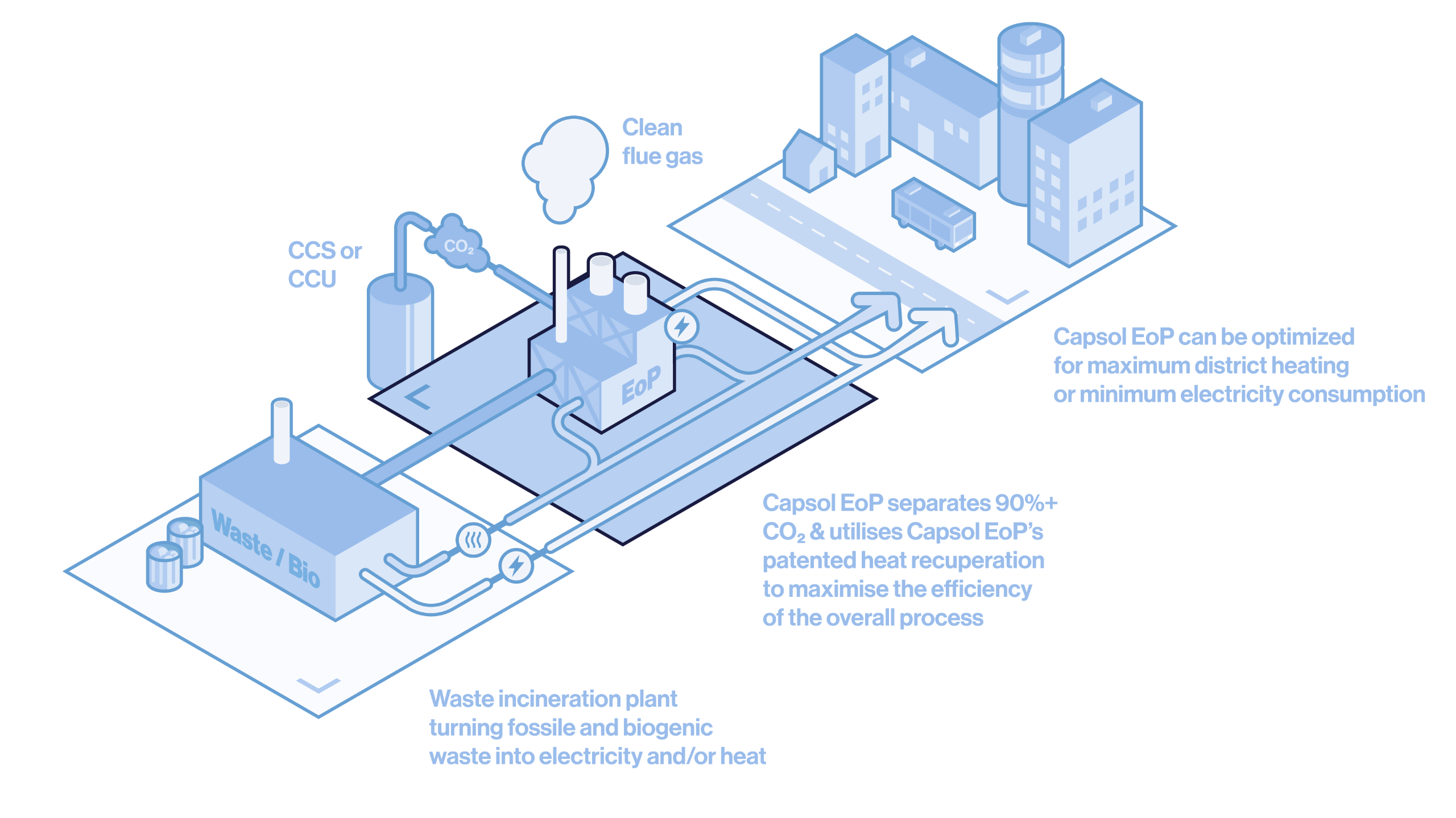

Capsol's Energy-from-Waste (EfW) decarbonization solution

Capsol’s significant cost advantages can be explained by these technical highlights.

Additional district heating generation

For customers that are connected to a district heating network, our CapsolEoP® solution can boost their energy production during winter months. Here our technology makes a capture facility an additional revenue generator.

Engineering work for clients has produced energy consumption numbers of 0.7-1.5 GJ/tonnes of CO₂ captured, depending on the composition and temperature of the flue gas (not including liquefaction).

Low energy consumption and fully electric

A Capsol carbon capture plant can be solely powered by electricity, which results in an overall low energy consumption due to the highly efficient internal heat pump effect for the conversion from electricity to heat.

Stand-alone unit simplifies integration

Our technologies are designed as stand-alone units that limits modification needs of customer’s facilities and minimize downtime of the customer’s plant during the construction period. Simpler integration reduces capex and project risk.

Safe and cost-effective handling of solvent

Our proven and safe HPC (hot potassium carbonate) solvent is relatively cheap and available globally. This is different to Amines, where emitters may be locked in with one expensive solvent supplier. In addition, HPC offers superior HSE (health, safety and environment) and easier permitting.

Case study Energy-from-Waste CCS project

CapsolEoP® adresses customer needs to provide additional revenue streams

The main portion of the opex for all technologies is the cost of energy needed to drive the CO₂ separation process. Energy can make up 70% of total opex costs. Compared with Amine technology, our advantage on energy savings increases with higher CO₂ concentrations.

The incentives for EfW is slightly different than for the cement industry. In addition to the ETS cost reduction and low carbon premiums, companies can also benefit from selling Carbon Direct Removal (CDR) certificates.

Looking at the graph to the left, in case of an Amine unit (Kalundborg), the margin between CCS costs and incentives is just 6 Euro.

In Capsol's case the marging can be multiple times higher with 74-94 Euro. This is explained by our technology advantage. EfW plants in central and northern Europe are often connected to district heating networks. During the winter our technology can generate energy for district heating. This creates an additional revenue stream for our clients. In this case 46 Euro - which leads to a very attractive overall project margin of 74-94 Euro per ton of CO₂ captured.

There are over 500 energy from waste plants in Europe.

Assumptions:218,000 tons waste processed, 200,000 tonnes CO₂ -emissions, 50% biogenic CO₂ split, 92% capture efficiency, no biogenic CO₂ prioritization in carbon accounting, no free EU ETS allowances, 20% green premium on electricity and gate fees, 75% utilization of district heating, Coefficient of Performance of 7.27, heat output at 100c, EUR 150 per CDR credit, EUR 100 per EU emissions allowance, electricity cost of EUR100/MWh, district heat revenue of EUR 83.5/MWh. All-in CCS costs, excl. general district heating costs such as distribution networks, maintenance, etc. https://www.capturemap.no/the-ccs-potential-for-waste-to-energy-plants/

High-level overview of Capsol's solution for EfW

We care. We can. We capture.

Learn how Capsol can help you reduce CO₂-emissions and significantly reduce capture costs.