About us

Your Technology and Project Partner for HPC Carbon Capture

Capsol’s post-combustion carbon capture and heat recovery system in one delivers superior efficiency with a proven and safe solvent.

Capsol’s technologies are applicable to all hard-to-abate industries and deliver superior performance throughout the entire capture process, ensuring safe operations and industry-leading capture costs. Capsol’s solutions utilize the nontoxic and non-degradable HPC solvent, with superior HSE profile making permitting easier. The technology is licensed either directly to customers or through industrial partners globally.

VISION

To accelerate the world's transition to a net zero future

MISSION

Deliver energy-efficient and safe carbon capture technologies

Technology description

Capsol's technologies are based on 15+ years of R&D, can run fully electric, requires no external steam, and has little to no water need. The technologies are built on a continuously growing base of patents for energy-efficient post-combustion carbon capture, currently with active patents across 11 patent families. The first successful test of the technology was performed in 2008 at the Värtan combined heat and power (CHP) plant in Stockholm, Sweden.

Capsol currently operates three carbon capture (CapsolGo®) and two liquefaction demonstration units on several flue gas streams in Europe. The CapsolGo® demonstration units are a powerful tool to introduce safe carbon capture to various stakeholders. It also offers the opportunity to verify the technology's effectiveness on the emitter's flue gas, accelerating the process towards a full-scale capture plant. In total, our units and previous tests have 19,000+ hours of operation.You can read more about the CapsolGo® demonstration units here.

Capsol’s technology platform with inherent heat recuperation and generation is applicable to all hard-to-abate industries with flue gas CO₂ concentration levels from 3-30% and delivers superior performance throughout the entire capture process, ensuring safe operations and industry-leading capture costs. The CO₂ purity of the dried gas exceeds 99%, meeting storage and utilization requirements.

The safe HPC solvent

An increasing number of industrial facilities are aware of the advantages of using the safe and proven potassium carbonate (HPC) solvent - which is well-documented and used in hundreds of plants globally in multiple industries, like lower capture and material costs, the solvent being widely available and no risk of harmful emissions. In addition, the solvent’s superior HSE performance eases permitting and limits supply chain risks.

Stand-alone capture unit

Capsol’s pressurized absorber design uses less plot space than competing technologies, and the standalone solution allows for easy retrofit and requires no modifications or downtime at parent plant during installation, commissioning or maintenance. By using well-known and widely used components, plant lead times can be between 18 and 24 months.

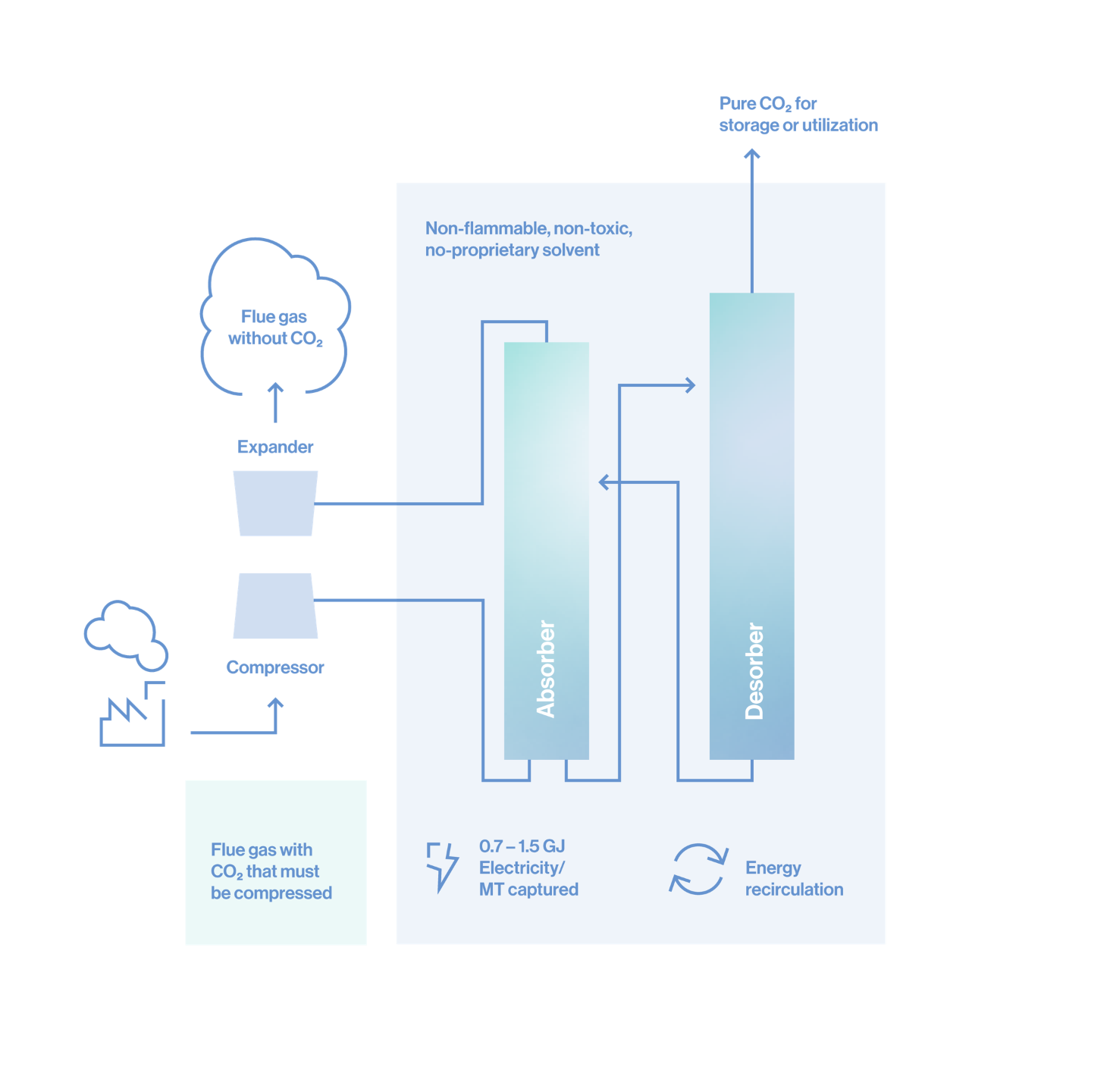

Capsol 's HPC process

The use of HPC for post-combustion (from flue gases) carbon-capture was, until recently, discarded as a viable option due to the high energy demand (and cost) required to pressurize the flue gas before it enters the absorber. To solve this, Capsol developed the CapsolEoP® solution – a standalone, retrofit unit, with inherent heat recovery and generation, offering low capture cost and the flexibility to monetize heat and electricity in the capture process. The capture unit can run on electricity only and there is no need to build an additional boiler for steam production. The electrical energy consumption is between 0.5 and 1.5 GJ/tonnes of CO₂ captured, depending on the composition and temperature of the flue gas.

The history behind Capsol's proprietary technologies

Capsol Technologies' carbon capture technologies are based on a chemical process using the safe potassium carbonate (HPC) solvent.

HPC as a solvent has been used to capture carbon dioxide for many decades (pre-combustion), with hundreds of HPC plants in commercial operation in the chemical process industry.

The technology was initially invented and developed by the U.S. Bureau of Mines in the 1940s and 50s, with further developments made in the 1970s. It is a robust, non-degradable (in the presence of oxygen), easily accessible absorbent, and is field proven for medium to large scale processes.

The development of Capsol Technologies' proprietary HPC technology for post-combustion CO₂ capture combustion CO₂ capture started in 2003.

The first successful tests of the technology were performed at the Värtan combined heat and power (CHP) plant in Stockholm, Sweden, in 2008. The tests performed at Värtaverket showed a high CO₂ capture efficiency of >98%.

In 2016, Stockholm Exergi commissioned a new CHP plant KVV8, at Värtaverket, which is run on wood chips based on forestry residues such as tree branches and tops as the main fuel (i.e. the plant utilizes secondary biomass).

In July 2022, Stockholm Exergi signed a Patent License agreement for the use of Capsol's HPC technology for carbon dioxide capture at their plant KVV8. The facility has the potential of capturing 800,000 tonnes of CO₂ per year, making it Europe's first large-scale plant with negative CO₂-emissions when operational.