Biomass

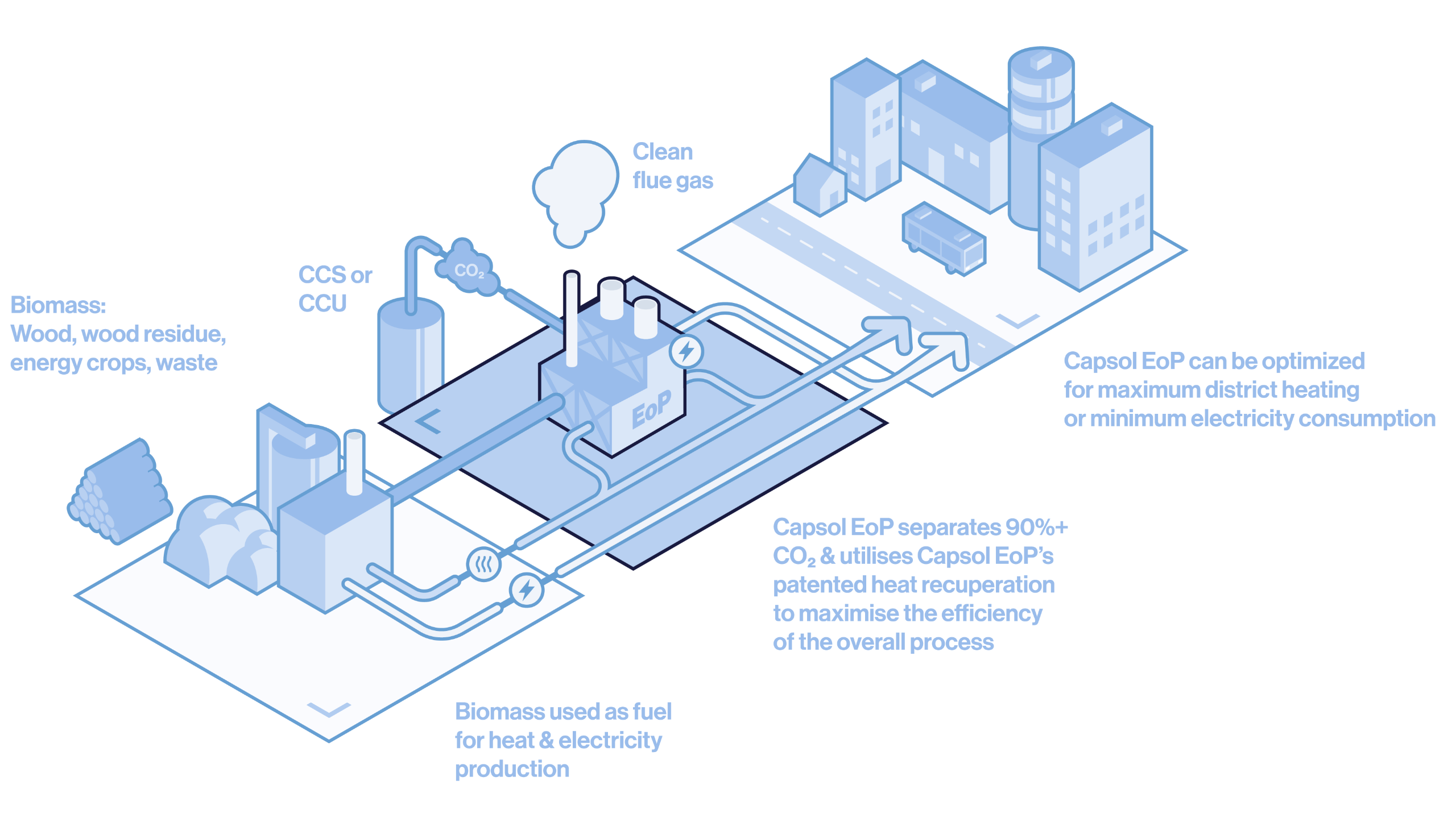

Capsol's carbon capture solution for biomass

Inherent heat recovery brings down cost

Capsol's carbon capture technology combines inherent heat recovery and generation in a stand-alone unit based on the proven and safe HPC solvent, bringing down the cost per ton CO₂ captured.

Engineering work for clients has produced energy consumption numbers of 0.7-1.5 GJ per ton of CO₂ captured, depending on the composition and temperature of the flue gas (not including liquefaction).

Poven and safe HPC solvent

Our proven and safe HPC (Hot Potassium carbonate) solvent offers superior HSE (Health, Safety and Environment) and easier permitting.

Stand-alone capture unit

CapsolEoP® is a stand-alone unit requiring minimal modification of the parent plant, with little to no water need. Simpler integration reduces capex and project risk.

High-level overview of Capsol's solution for cement

Stockholm Exergi - Europe's largest BECCS project - will be using CapsolEoP®

Stockholm Exergi is one of the first companies in the world to develop a model for enabling the shift from reduced carbon dioxide emissions to negative emissions.

Bio-energy with Carbon Capture and Storage (BECCS) is one possible way of slowing global warming and ultimately rebalancing the climate sustainably. Stockholm Exergi’s calculations show that there is potential to capture 800,000 tonnes of carbon dioxide per year.

Stockholm Exergi’s plans for a BECCS plant at their biofuel-fired CHP (Combined Heat and Power) plant are becoming increasingly well-defined and we are happy that Stockholm Exergi has chosen our CapsolEoP® solution for this first-of-a-kind large-scale bio-energy carbon capture plant.

Your experts on Biomass Carbon Capture

Cato Christiansen

Stellan Hamrin